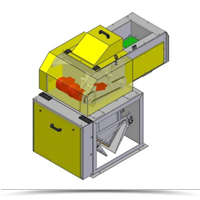

Belt Feed Weighers are suitable for free and non-free flowing products like detergent, seeds, grain, sand, free-flowing powders, animal feed, bran, chips, rice, wheat, plastic granules, fertilizers, sugar, tea etc. The quantity fed during course feed, fine feed and super fine feed modes, depends on the flow characteristics of the material and the flow rates are adjusted using product gate.

Belt Feed Weighers are suitable for free and non-free flowing products like detergent, seeds, grain, sand, free-flowing powders, animal feed, bran, chips, rice, wheat, plastic granules, fertilizers, sugar, tea etc. The quantity fed during course feed, fine feed and super fine feed modes, depends on the flow characteristics of the material and the flow rates are adjusted using product gate.

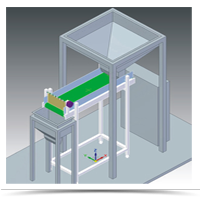

These are basically available in three capacities viz. up to 1.5 kg, 6 kg and 50 kg. The number of filling heads is configured depending on speed required.

Sometimes pneumatic operated gates are offered at the end of the belt to arrest uncontrolled fall of products such as seeds, while stopping the belt.

Functions

• Compact and modular design.

• High accuracy at high speeds.

• Two / Three stage feed system.

• 1 ~ 6 heads for weighing and dispensing.

• Contact parts are of stainless steel.

• Easy cleaning.

• Caters wide range of products and can be retrofitted into all bagging machines.

• Bag filling spout (optional).

• Weighing speed up to 6000 weighments per hour.

» Technical Specifications

Note:

(a) * Depending on product characteristics, weight and number of filling heads.

| OptiWeigh Belt Feed Weigher |

FW-1.5-X-B | FW-6-X-B | FW-50-X-B |

| Number of Weighing heads( X) | 1 to 6 | 1 to 3 | 1 & 2 |

| Weighing range per head | Up to 1.5 kg | Up to 6 kg | Up to 50 kg |

| Weighing Speed * | Up to 100 weighing /min | Up to 35 weighing /min | Up to 30 weighing /min |

| Accuracy* | On request and after product test. | ||

| Power Supply | 230 volts, 50 Hz, 1 phase 3 wires, 500 VA per head | 230 volts, 50 Hz, 1 phase 3 wires, 500 VA per head. | 230 volts, 50 Hz, 1 phase 3 wires, 750 VA per head. |

| Air Pressure | 4-6 bars | 4-6 bars | 4-6 bars |

| Temperature | 5° C - 40° C | 5° C - 40° C | 5° C - 40° C |

| Bag filling spout (SS) | Optional | Optional | Optional |

| SMounting stand (MS painted) | Optional | Optional | Optional |